Evaluate your Roof Ventilation in fire risk areas

Roof ventilation in BAL high fire risk areas is a problem requiring consideration.

Not because of what is known, but more about what isn’t.

Anyone can induce fear of the unknown by making various claims to suit their agenda.

Most claims are designed to impact on the emotional ignorance.

Understanding

The greatest cause of house fires in rural areas is air borne embers as well as fire proximity to the house.

Embers do not enter against the flow of a roof ventilator but can and do enter via poorly sealed flashings.

Plastic eaves vents will degrade with heat and pressure.

Eaves vents used in high fire risk locations should be stainless steel material with nominal aperture size of 2mm.

Fine woven wire, such as fly wire, has a tendency to clog up with dust and become ineffective.

Approach

At this point one prudently errs on the side of caution as roof ventilation.

It is essential to maintain a pressure equilibrium between internal and ambient of the building.

Filter barriers can be employed to address ingress.

Selection

Before you stuff mesh into the throat of your roof ventilator ask yourself 3 questions…

1/ is this going to stop present performance?….

2/ by how much?….

3/ what are the consequences?

If the mesh, or screen has a resistance value of 50% then you’ve just wiped out 50% of the ventilator performance.

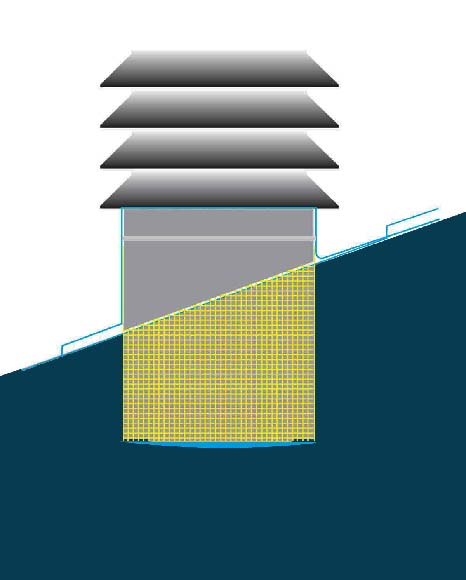

The surface area of any screen device used has to be equal to the open area of the roof ventilator throat therefore the ember screen should look something like as below.

The ideal nominal hole size to use is approx 2mm in stainless steel material preferably perforated sheet, not woven wire.

Do not use fly wire, or similar, as these will clog up with dust, require continual maintenance.

Do not install if ‘free air flow” cannot be verified.

The screen supplied needs to be equal to, or above, the free air value of the throat of your roof ventilator.

Condor